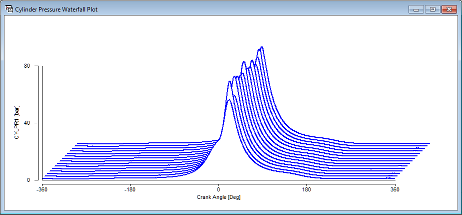

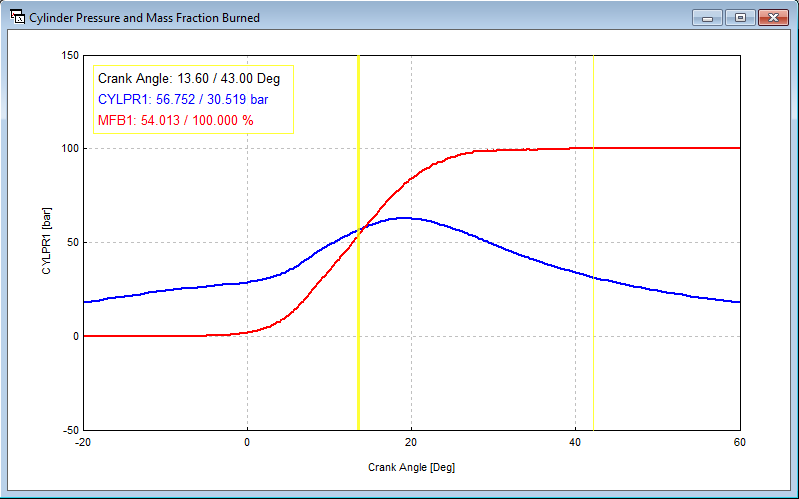

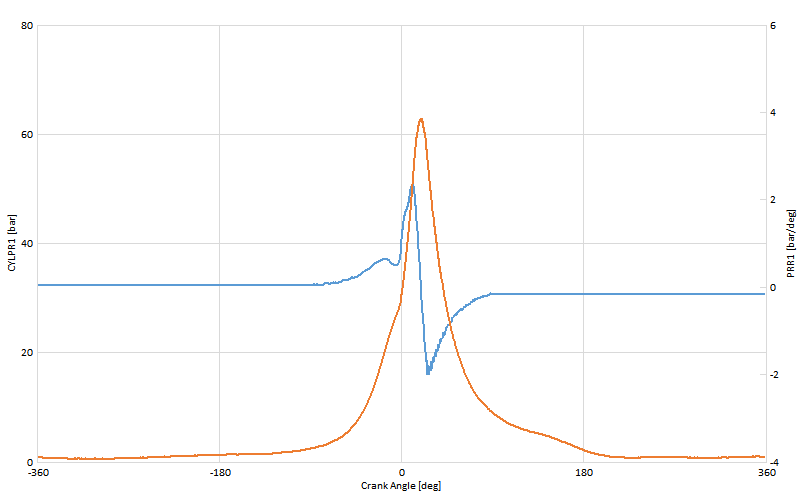

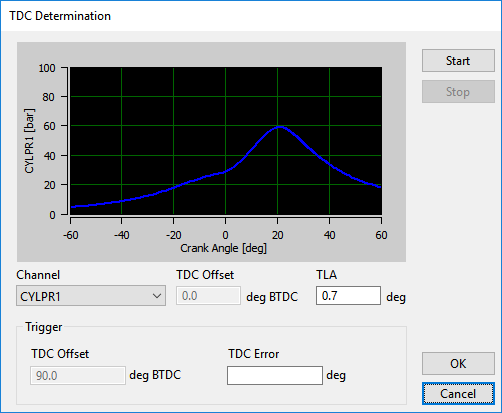

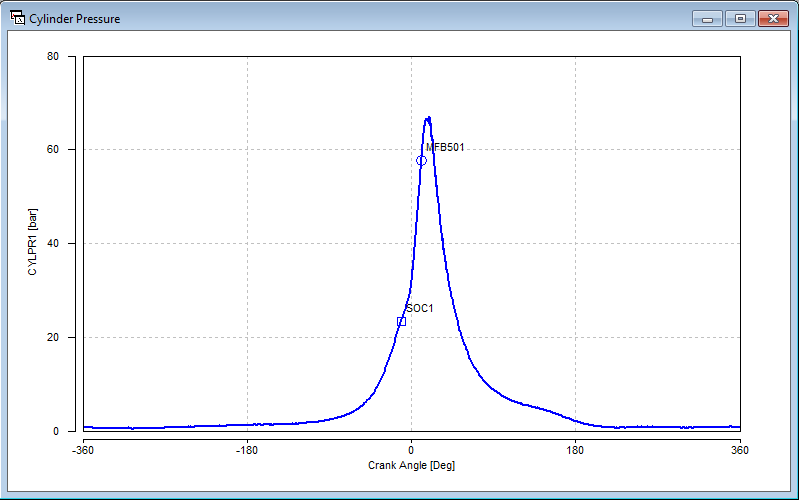

Crankangle Diagrams

Standard cylinder pressure crank angle diagram. The positions of Start of Combustion (SOC) and MFB50 identified on diagram.

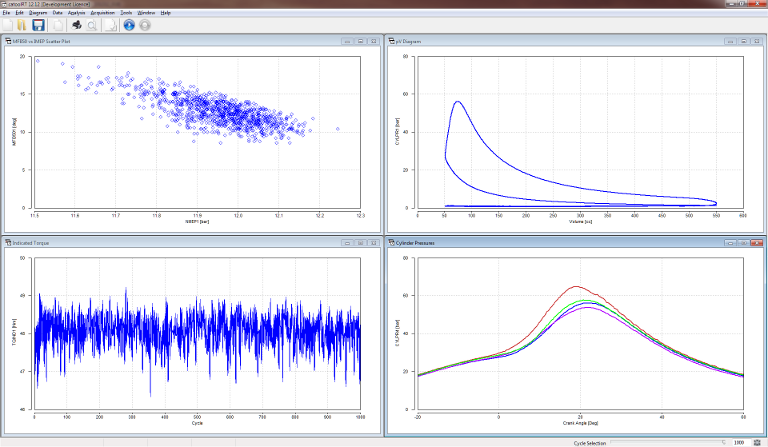

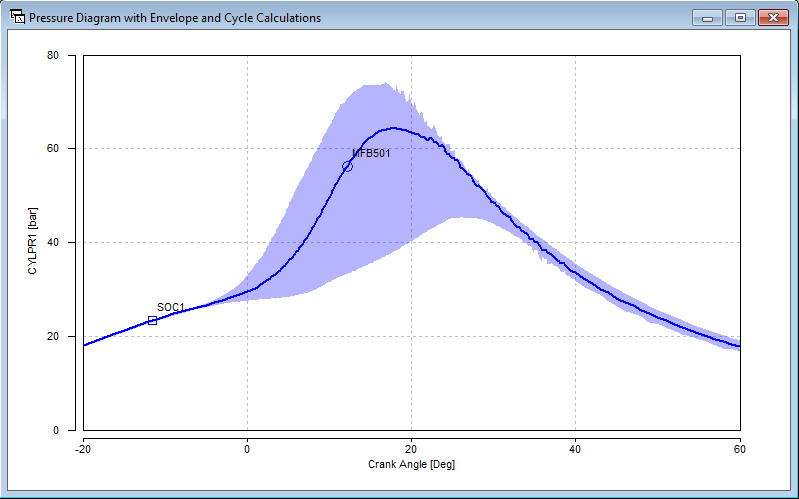

Data Envelope

Cylinder pressure plot with SOC and MFB50 again identified. The cylinder pressure envelope has been plotted to indicate the range of data. The envelope could also be from another data file so you can compare current combustion data to a reference condition.

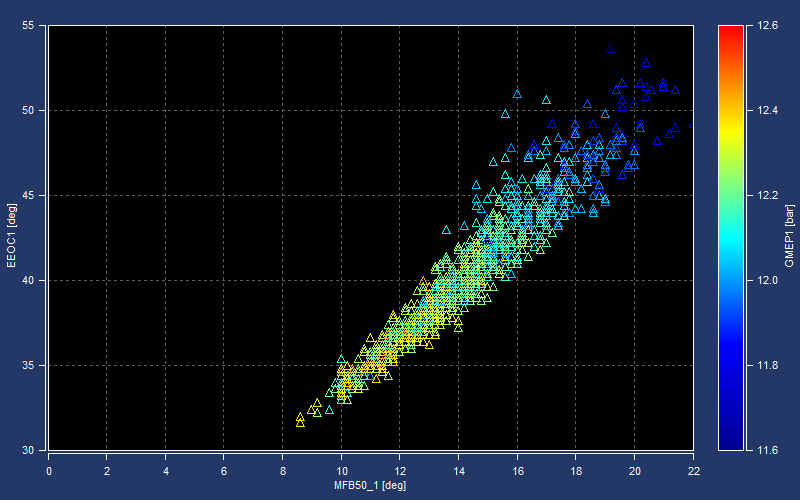

Pseudo 3D Diagrams

Pseudo 3D plot of MFB50 versus Estimate End of Combustion. Marker colour is colour map of GMEP. Diagram style of AVL Blue (IndiCom)

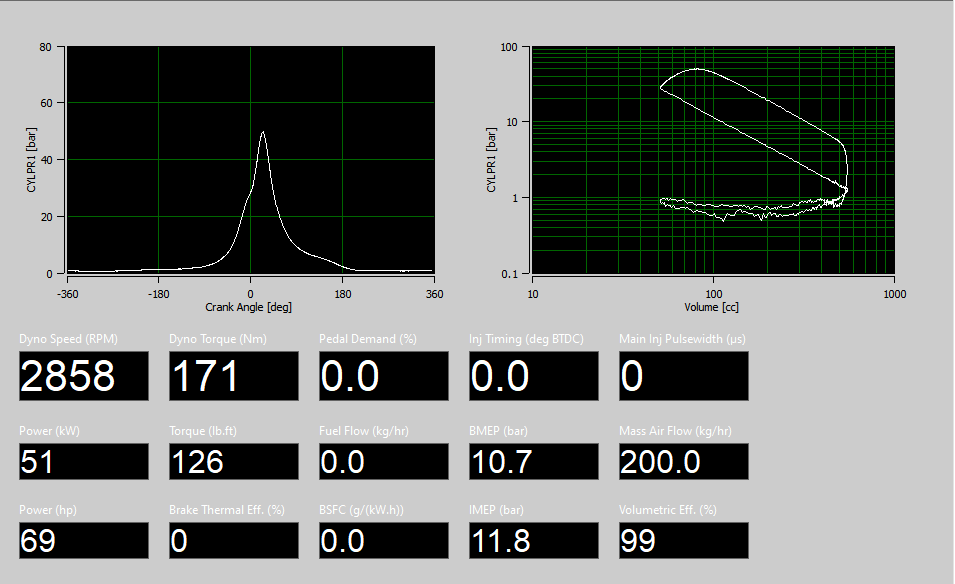

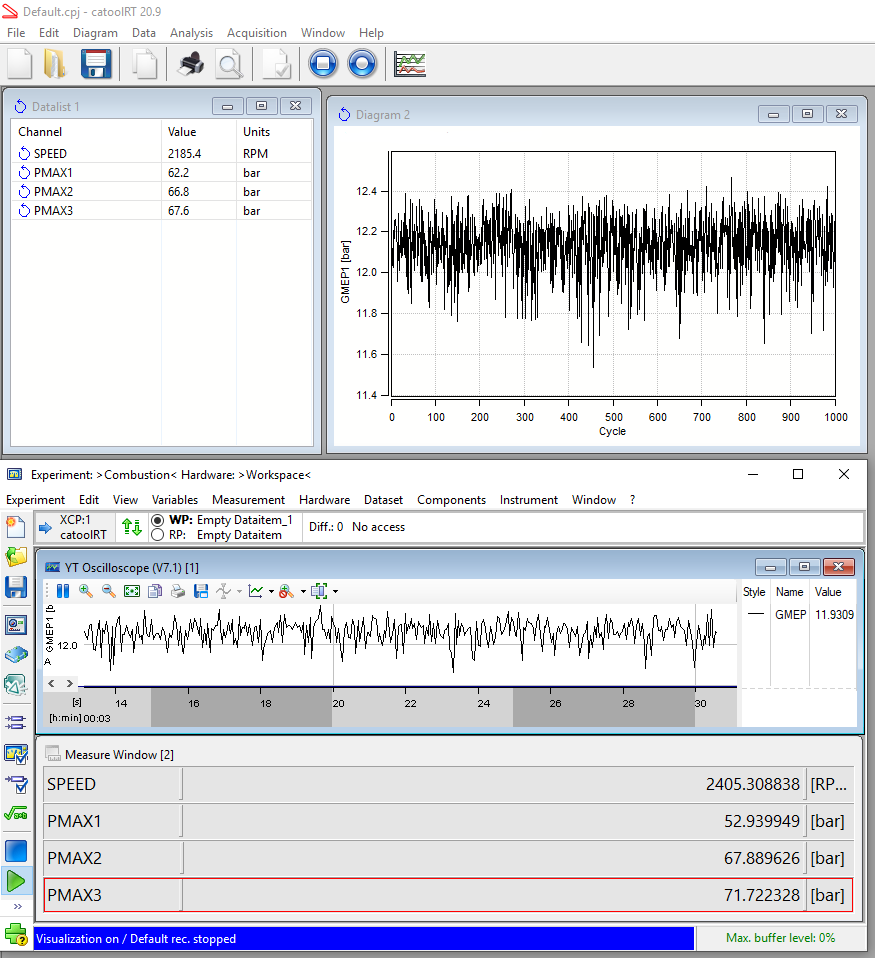

Data Lists

Datalist of current cycle calculations including minimum, maximum, mean and standard deviation statistics.

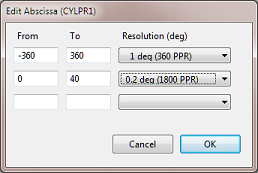

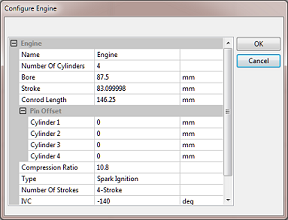

Engine Configuration

The engine geometry and type is fully configurable. catoolRT supports spark and compression ignition, 2 and 4 stroke cycles and any number of cylinders.

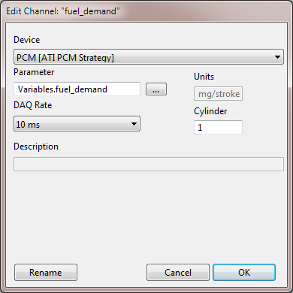

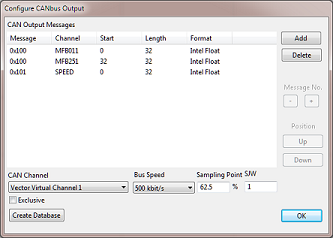

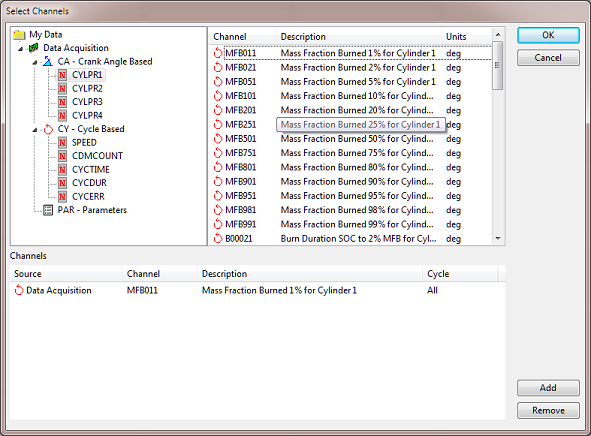

Channel Selection

Selecting data for display or CAN output is simple. Select the raw channel in the tree on the left of the window and a list of analysis channels is displayed for selection.

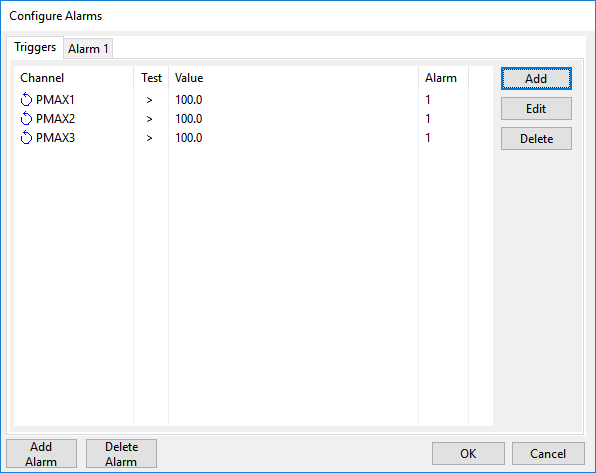

Alarms

Configure alarms to trigger on-screen warning messages, output CAN message and/or trigger digital output

Calibration Synchronisation (CalSyncTM)

Log fully time aligned combustion analysis with PCM parameters. Note that cycle calculations are available at the start of the combustion cycle.